Cannabis Automation Leader Unveils Plans for the Next Generation of Commercial Trimming Equipment

Las Vegas, NV, February 18, 2025 — Mobius, a global leader in post-harvest cannabis automation equipment, has released its Concepts in Development preview, along with the launch of their newest models of trimming machines, detailing the strides they have made in advancing technology in the cannabis processing sector. Launching four new trimmer design concepts, the company is significantly progressing in the post-harvest space.

These advanced machines are set to redefine post-harvest processing by enhancing operational efficiency, ease of use, and reliability for commercial cultivators and processors. Mobius debuted these new models at the 2024 MJBizCon in Las Vegas, providing attendees with an exclusive first look.

With the continued evolution of the cannabis market, Mobius recognizes the industry’s need for versatile, high-capacity trimming solutions that maintain quality while maximizing throughput. These new models are engineered to address these demands with precision, designed with input from leading cultivators to address pain points that have long hindered large-scale cannabis operations. By leveraging advanced technology and ergonomic design, Mobius is driving a new standard of performance and reliability in cannabis trimming.

“Mobius is dedicated to advancing the cannabis industry through continuous innovation,” said JJ Fabian, Director of Sales and Business Development. “These new trimming solutions showcase our commitment to meeting the evolving needs of our customers, helping them achieve greater productivity and consistent quality while reducing labor demands and costs. Our in-house research and development teams have been iterating on the trimmer designs, ensuring every aspect of each machine is optimized to deliver the best trimming results,” said Fabian.

These new trimming innovations come at an opportune time when the global cannabis trimming machines market has projections for a steady growth rate, expected to reach a compound annual growth rate (CAGR) of around 8.5% through 2028. This growth is driven by the rising demand for cannabis trimming solutions that deliver high-quality products on a commercial scale. With the increasing utilization of automated cannabis processing equipment in the industry, technological advancements and commitment to innovation for cultivators are what will deliver the best results to consumers.

With growing legalization and demand for high-quality cannabis products, the processing equipment needs to evolve to match the market growth, just as the market is evolving with new product categories and trends. This symbiotic relationship is evident as the industry experiences upward movement across the board. By enhancing the consistency of the trimming process and boosting the efficiency of the systems, cultivators achieve a streamlined process with reduced labor and operating costs.

The first of the newest trimmers will be launching this March, featuring Mobius’ T-Line, including the TD15 and TD25 dry trimmers. The trimmers are designed to revolutionize commercial cannabis processing with advanced design, efficiency, and precision. The TD15 and TD25 dry trimmers are purpose-built for dedicated dry trimming, offering customized solutions to accommodate different cannabis types and processing scales, making them highly adaptable to various operational needs.

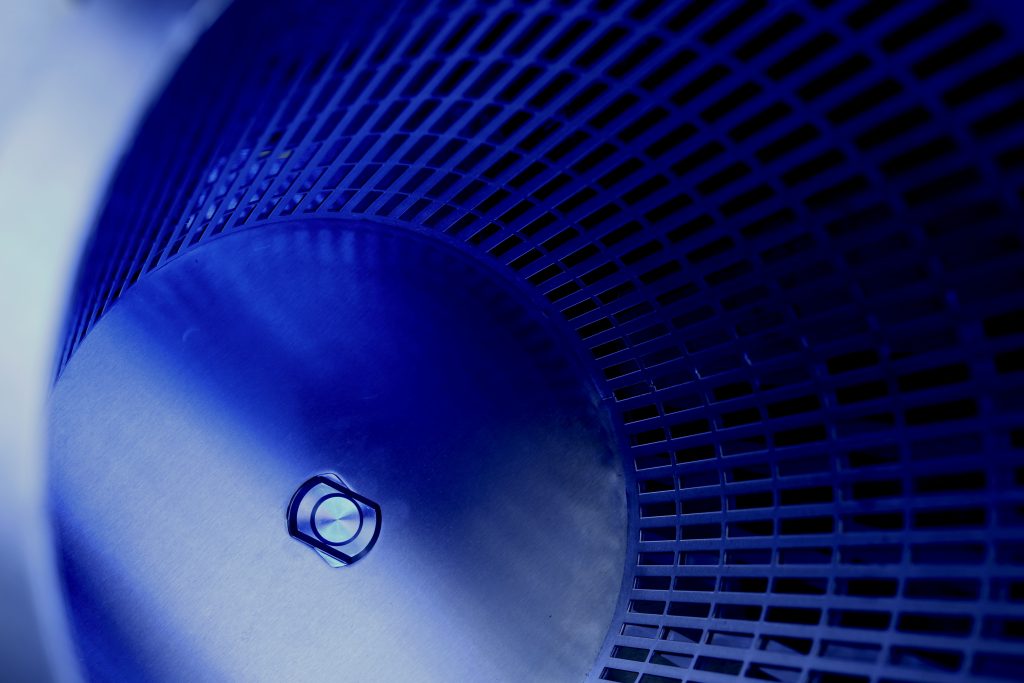

The T-Line trimmers are GMP-ready with a stainless steel construction and are designed to be portable, versatile, and easy to use for any harvesting workflow. The TD15 and TD25 are also vacuum and lubricant-free, ensuring you deliver premium top-shelf flower and pure trim. Available in two different sizes, you can find the trimming capacity that best suits your needs, with the TD15 trimming up to 10 lbs/hour and the TD25 trimming 24 lbs/hour.

For operations requiring even greater capacity for dry trimming, Mobius is unveiling the MD48. This dedicated dry trimmer is optimized for gentle handling and maintains the integrity and quality of cannabis buds while achieving high-speed commercial throughputs. The MD48 will feature a stainless steel body, is washdown-rated, and is ready for use in any GMP-certified facility. This new dry trimmer design allows for faster and easier loading and unloading of the machine, thus reducing downtime in the process. The auto-tensioning shear band technology eliminates the need for any lubricants or vacuums, ensuring your flower remains trichome-rich. The auto-tensioning system also allows for seamless drum removal and swaps for fast, tool-free cleaning, or non-stop trimming action. Easily swap in the optional kief kit for kief extraction without having to re-tension your machine.

Featuring an intuitive touchscreen control, the MD48 will let the user create trimming recipes, allowing you to track and save settings such as tilt levels, tumbler speeds, and timers. This creates a streamlined workflow for every harvest based on throughputs, strain type, and moisture content, delivering ultra-consistent trimming results with each run. Integrated oscillating technology and tilting features will pitch the unit back and forth, mixing the flower more efficiently and speeding up the trimming process.

After almost 10 years of serving the industry’s leading cannabis producers, the flagship Mobius trimmer has also been updated. Now the M108X, this new model has been revamped with all of the same Mobius trimming technology cultivators know and love, with additional upgraded features. The M108X has a fully stainless steel construction for pharmaceutical and food-grade compliance, easily fitting into any GMP facility. With a 50% stronger vacuum, the new M108X will deliver the tightest, hand-quality trim cultivators have ever achieved on a commercial scale. The trimmer will also feature a touchscreen interface for more advanced controls like recipe saving, tandem operation, and conveyor control.

These new trimmer models are crafted to meet Mobius’ high standards of quality and innovation, with robust components and precision engineering ensuring years of reliable performance.

As Mobius continues to lead in cannabis processing automation, these new trimmers underscore the company’s ongoing commitment to innovation and support for the rapidly growing cannabis industry.

The TD15 and TD25 trimmers are available now for pre-order. For more information about Mobius and its cutting-edge cannabis automation equipment, or to learn more about the new T-Line dry trimmers, please email info@mobiustrimmer.com.

Contact: JJ Fabian, Director of Sales and Business Development

Phone: 866-874-6244

Email: info@mobiustrimmer.com

###